1. Surface deformation strengthening technology

1) Mold peening and action

The shot peening process is a process in which a large number of projectiles are sprayed onto the surface of the part, and the projectile is sprayed onto the surface of the part as if numerous hammers hit the surface. Therefore, the surface of the metal part is extremely strongly plastically deformed, so that the surface of the mold has a certain thickness. The cold work hardening layer, called the surface strengthening layer, significantly improves the fatigue strength of the part under high temperature and high stress working conditions.

2) Surface changes of shot peening

(1) Macroscopic residual stress.

(2) Microscopic stress of the surface layer.

(3) Micro-embedded structure of the surface layer.

3) Shot blasting machine and shot peening process parameters

The shot blasting machine has a pneumatic blasting machine and a centrifugal blasting machine. The pneumatic blasting machine is a compressed air supplied by an air compressor that causes a negative pressure to pass the projectile and sucks the nozzle at a high speed to form a surface of the part of the projectile jet. There is also a mechanism for moving the parts in the shot blasting machine to ensure the uniformity of the shot peening and a certain coverage. Shot peening mainly controls the shot peening strength. There is a certain shot peening strength for any given blasting operation condition, but it is necessary to determine the arc height curve to determine the shot peening strength.

2. Coating modification technology of mold

1) The hard chrome plating method plays an important role in the surface strengthening of some molds. It has the advantages of small coating friction coefficient, high hardness (about 1100 HV), simple application and repeated treatment. However, it should be noted that if the thickness of the coating is unreasonably selected, the mold will be damaged prematurely. When the mold is subjected to strong pressure or impact, the plating layer is easily peeled off, causing premature failure of the mold. Therefore, cold dies and punching dies cannot be plated with hard chrome, and it is only suitable for molds such as press bending and forming with less stress.

2) Nickel-plated phosphorus alloy

Immersing the pretreated workpiece into a solution containing nickel salt, reducing agent and other additives will cause an autocatalytic reduction reaction on the surface of the workpiece to reduce the nickel ions in the solution to metal and deposit on the surface of the workpiece (mold). A plating layer is formed.

3) Chemical vapor deposition

The method of surface coating according to the principle of chemical deposition is called chemical vapor deposition, abbreviated as CVD. The working part of the mold which needs to be permeable layer is heated to about 1000 ° C in a vacuum, and then leads to a reaction gas such as TiCl4, H2, CH4, etc., the gas encounters a high temperature working surface, and a compound such as TiN and TiC can be formed under the action of high temperature, and Firmly adhere to the surface of the mold part to form a super-hard coating.

OREMA's commitment to innovative, efficient, and reliable battery solutions has established us as a global leader in the industry. OREMA General Purpose AGM Batteries, embodying this commitment, are designed with advanced valve-regulated lead-acid technology. These Vrla batteries are exported to over 80 countries, meeting the diverse needs of various sectors.

OREMA UN Series General Purpose AGM Batteries: A Blend of Technology and Versatility

The OREMA UN series AGM batteries are a product of meticulous engineering, designed to cater to a broad spectrum of applications. With a wide range of capacities and models, these Sla batteries are equipped with AGM technology, ensuring sealed safety, low internal resistance, and high-sealed reaction efficiency. They are particularly suitable for use in communication systems, power systems, uninterrupted power supplies (UPS), solar energy systems, and alarm, fire, and security systems.- Deep Cycle Performance: The UN series batteries excel in small current deep cycle discharge, boasting a long cycle life and strong overcharge resistance at high temperatures.

- Rapid Recovery Post-Discharge: These batteries quickly recover their capacity after deep discharge, ensuring consistent performance.

- Advanced Sealing Technology: Utilizing automated heat sealing and epoxy resin automatic filling, coupled with TTP welding technology, the UN series guarantees no electrolyte leakage, ensuring reliability and maintenance-free operation.

- Wide Operating Temperature Range: Ideal for outdoor use in various environments, these batteries are characterized by uniformity and low internal resistance.

Key Features of OREMA General Purpose Battery:

1. Extended Discharge Performance: Superior discharge characteristics over extended periods.2. Versatility: Ideal for both standby and energy storage applications.

3. Durable Plate Design: Enhanced plate construction for a long service life.

4. Innovative Lead-Calcium Alloy Formula: Increases corrosion resistance.

5. Specialized Separators: Boost internal performance.

6. High Thermal Capacity: Reduces the risk of thermal runaway.

7. Efficient Gas Recombination: High efficiency in gas recombination.

8. Minimal Water Loss: Virtually eliminates electrolyte stratification.

9. Extended Shelf Life: Longer storage periods without performance compromise.

10. Exceptional Deep Discharge Recovery: Rapid capacity recovery after deep discharges.

Application Scenarios for General Purpose AGM Batteries:

- Automotive and Electronics: Ideal for vehicles laden with electronics, marine, and RV applications.- Backup Systems and Emergency Lighting: Suitable for UPS systems and emergency lighting.

- Industrial and Commercial Uses: Exceptional performance in industrial equipment and commercial devices.

Unique Advantages of AGM Technology:

- Maintenance-Free: Designed to prevent acid spillage, reducing water loss during usage.- Charging Requirements: Special AGM chargers are required to maintain voltage below 14 volts.

- Optimized Electrolyte Utilization: Maximizes electrolyte surface area.

- Sealed Lead Acid Design: Known as Valve Regulated Lead Acid (VRLA), offering a leak-proof experience.

As a global leader in battery technology, OREMA and its OREMA AGM batteries offer more than just power; they represent a synergy of innovation and reliability. We invite battery purchasers and distributors to explore our cutting-edge products. Trust OREMA to empower your world with reliable and innovative energy solutions.

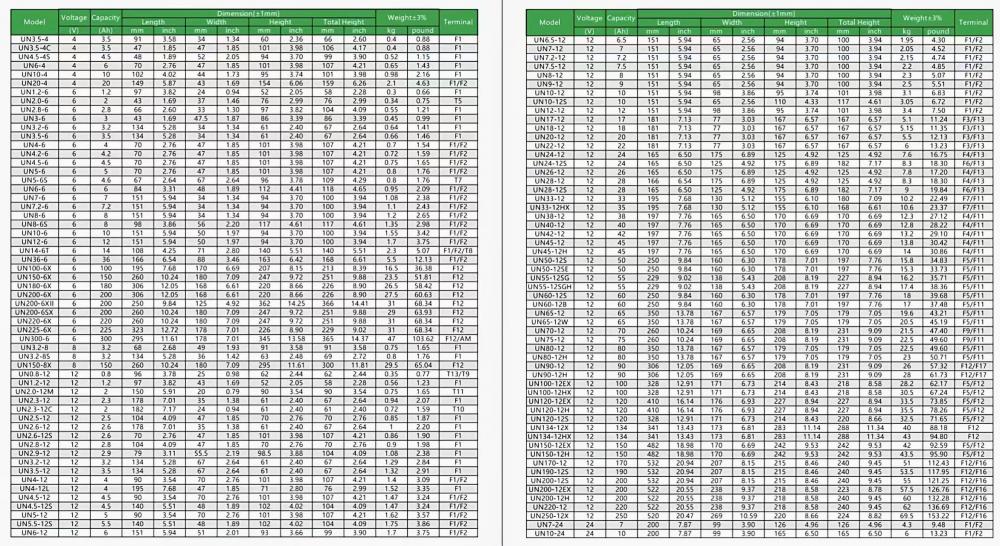

OREMA UN Series General Purpose Specification table of AGM Batteries

General Purpose AGM Batteries,VRLA Batteries,AGM Batteries,General Purpose Battery,SLA Batteries,VRLA Battery,SLA Battery

OREMA POWER CO., LTD. , https://www.oremapower.com